Transform Your Facility with Factory Floor Connectivity

Factory Floor Connectivity provides you with the capability to obtain real-time insights. Leave behind the practice of waiting for monthly reports to assess performance. With Dploy Solutions, you can track essential metrics, enabling agile and informed decision-making.

Dploy Solutions helps businesses of all sizes, in every industry:

Factory Floor Connectivity Capabilities

Factory Floor Connectivity provides you with the capability to obtain real-time insights into your factory performance. Every minute of the day keep the pulse on equipment health and address issues on the spot before production is impacted. With Dploy Solutions, you can track essential OEE (Overall Equipment Effectiveness) metrics, enabling agile and informed decision-making and problem-solving that will keep production on track with daily goals.

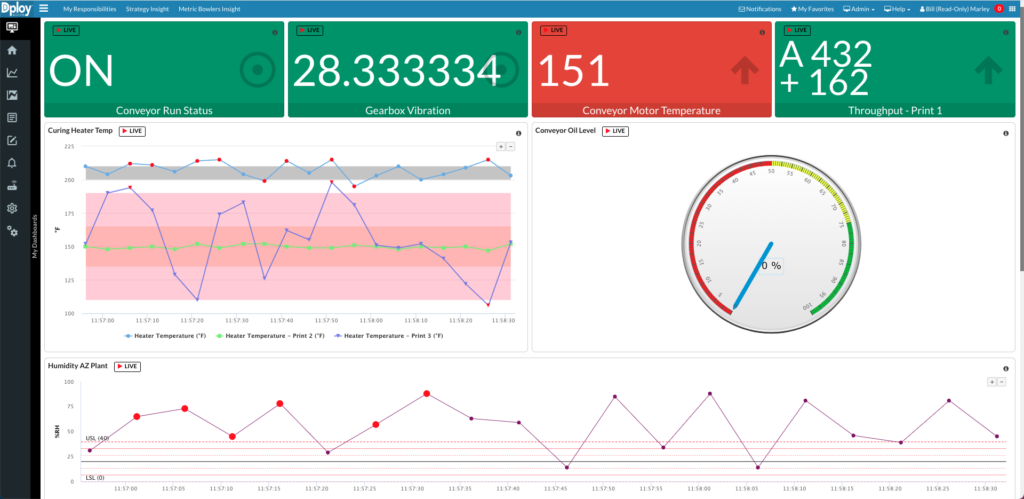

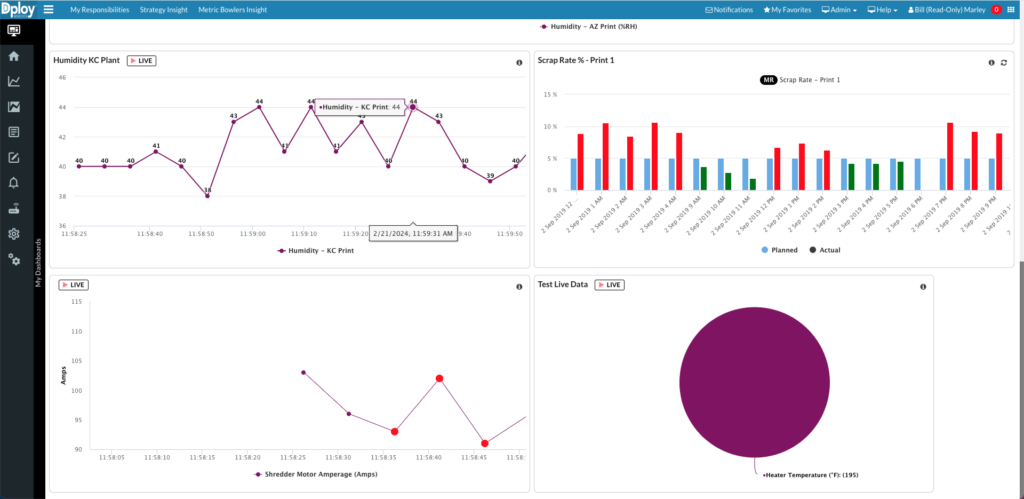

Dynamic Dashboards

Data is gathered and then made available to end-users in the format that works best for them. Embedded, interactive, and dynamic charting tools allow you to choose from a variety of chart and graph styles using easy drag-and-drop functionality and data filters.

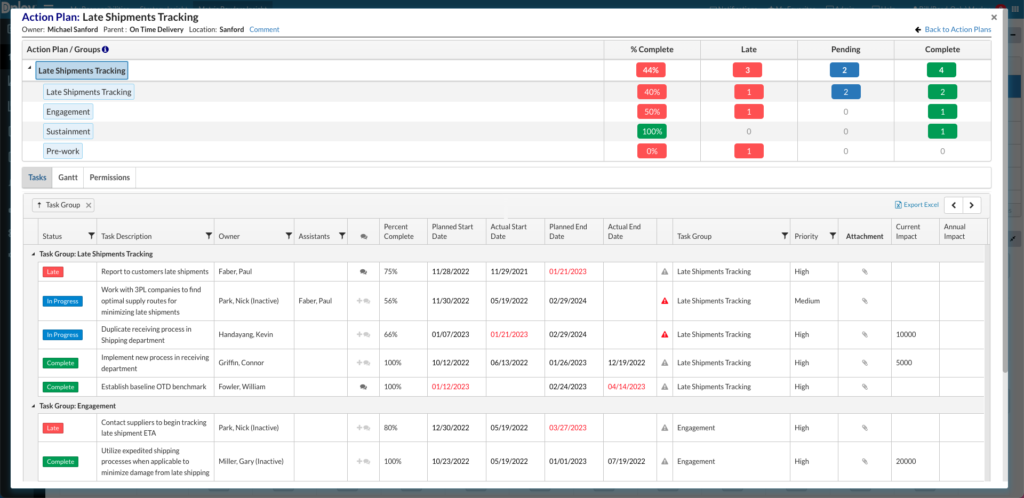

Alerts & Action Plans

Customizable alerts notify the right people via email or text when performance is off track on specific equipment or assembly lines. Alerts start at the lowest level. If problems cannot be resolved within a set timeframe, alerts are escalated up the chain of command.

Operational Historian

The operational historian collects historical data for real-time insights and analysis, empowering engineers, operators, and managers to improve production, quality, safety, efficiency, and reduce waste while managing maintenance.

Factory Floor Connectivity: Factory Floor Data Like You’ve Never Seen It Before

Dploy’s Factory Floor Connectivity capabilities provide a cost-effective, scalable solution for small to mid-sized manufacturers, allowing plant managers and equipment operators to monitor performance on the plant floor, address issues quickly, and sustain optimal performance. With our customer support and implementation services, you can get Dploy Solutions up and running fast – in days or weeks rather than months.

Frequently Asked Questions

1. What capabilities does Dploy Solutions offer for factory floor connectivity?

Dploy Solutions provides real-time connectivity to factory floor data, supporting over 140 protocols for smart devices, PLCs, control systems, and industrial IoT sensors. It offers historical data collection, dynamic and customizable digital dashboards, real-time alerts for issue escalation, and in-depth analytics for performance monitoring and improvement.

2. How does Dploy Solutions enhance data visibility and decision-making?

Our solution leverages advanced OPC client-server architecture and integrates data from various sources onto dynamic dashboards. These dashboards update in real-time, allowing for immediate visibility into operational performance, trend analysis, and issue detection, thus enabling quick decision-making and corrective actions.

3. Can Dploy Solutions handle both old and new technology protocols?

Yes, it supports over 140 different protocols, catering to both old and new technologies. This ensures that a wide range of devices, systems, and sensors can be connected and monitored, facilitating comprehensive factory floor oversight.

4. What kind of alerts and issue resolution support does Dploy Solutions provide?

It features customizable real-time alerts that notify the relevant personnel via email or text about performance deviations. It also allows for multi-level issue escalation and the creation of action plans for timely resolution, ensuring production stays on track.

5. How does the operational historian feature benefit users?

The operational historian collects and stores high-resolution historical data, which is integrated with visualization tools within Dploy Solutions. This enables users to review past performance trends, troubleshoot process and equipment problems, and make informed decisions to improve efficiency and reduce waste.